M3D series

What is 3D printing?

Sitting around in my comfort zone and exploring what the world has to offer, I stumbled upon this ever evolving space of 3D printing. So I started exploring it on YouTube and quickly got hooked up as to how far the technology has come and so much of choice we have in 3D printers as compared to 10 years ago. Not to mention that the sudden jump in this evolution was the result of multiple patents expiring for 3D printing in around 2014. Since then we have seen a lot of new players come in the market and provide a lot of solutions.

For those who are new to the 3D printing world, it’s an additive manufacturing technique where a product is manufactured by depositing a small amount of material, layer by layer on a build plate, until the whole product is formed. Depending on the technology i.e. Stereolithography (SLA), Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM) etc., the materials and processing varies. I will spare you the details but if you want to explore more here are a couple of links:

What technology do I use?

After going through hours and hours of research I narrowed down my preferred technology to FDM for numerous reasons. Not saying that the others are not any good, but for me personally running a home based business it was crucial. Here are the reasons why I choose the technology:

- Filaments come in roles called spools, much like electric wires do. They are easy to handle, have a long shelf life and can be recycled without losing much of their properties. So the failed 3D prints I have all go in a special bin that I will recycle some day.

- FDM filaments come in wide variety i.e. PLA, ABS, PETG, wood composite, carbon fiber, nylon and the list goes on. There is a huge range of colors too and especially PLA (Poly Lactic Acid) stands out of all the material types as the most versatile and non toxic material to use.

- PLA filaments are used for a wide variety of applications. PLA is derived from corn starch and is plastic like but far from it, as plastic is made from petroleum. So you can say up to an extent, it is environmentally friendly material to use, as long as you dispose of it responsibly or recycle it. Point to note here is that PLA lasts years if thrown away and will cause environmental pollution, if not leaching toxins in soil like petroleum plastic does.

What that means is that if I am running a good quality 3D printer with an air filter that is enclosed in a chamber, I get to run the device in my home office without having to worry too much about my health or that of people working in that space. In addition to it a good quality 3D printer has low noise and heat escaping in the environment with lots of additional benefits like remote monitoring, multiple spool material station, auto filament loader etc. I think you got the gist of it.

What did I print?

Getting access to 3D printer and a world of opportunities, my first intention was to learn the printing process and understand the printer at a very basic level on how it operates. What could be better to create a project that is small enough and precise enough for me to learn. So I wanted to create a smallest print probably one layer thick so I can understand how the printer actually works.

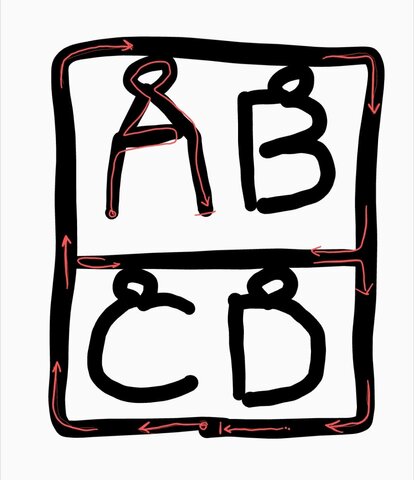

Having a good understanding of how the print head moves to drop molten filament on the build plate was important. In the above photo you can see that it is important for the print head to move in a particular flow along the red lines on stencil so it can create a seamless uniform print. Took me a while to understand various principles on which the printer works and the workflow from sketch to vector graphic to 3D model and sliced printable file. But the journey was worth it.

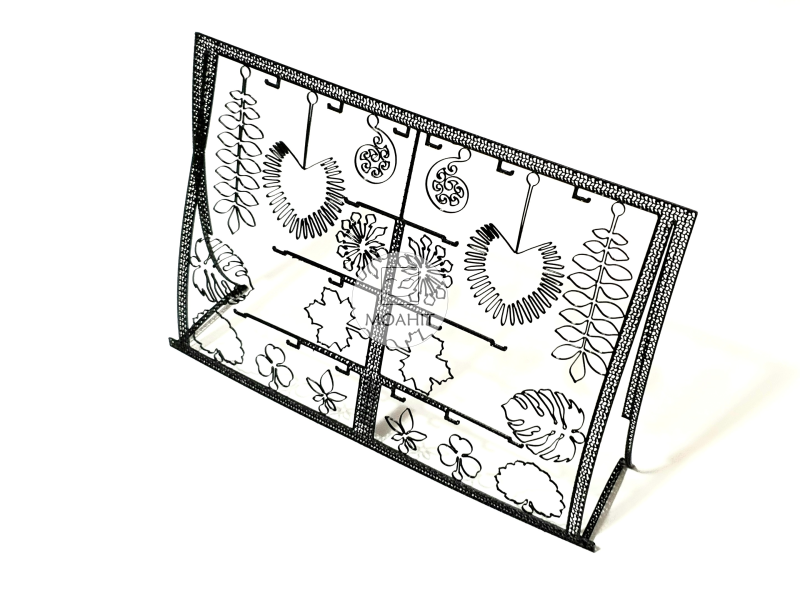

Believe it or not this was my first project which led me to the creation of the 3D printed jewelry set that I am selling now.

Creative aspect of the 3D jewelry set.

I wanted to combine the technique I learned above with my love for nature and art. Finding a product that I could produce and call my own was important for me rather than just printing that everybody else out there is. I did some sketch works and came up with a plan to create some jewelry pieces that could be created following the above principals. Hence my first floral design of 3D printed jewelry was born. From there on it was a matter of perfecting the art (which did take a whole lot of time) and getting closer to the end result.

Now that I had printed my first design successfully, I was in a position to mass produce it using the same file I have developed as many times as I want. It was a rewarding feeling. But the journey doesn’t end here, it has just begun 🙂

From here on lies a daunting task to promote the product and bring it to a larger audience ensuring the quality, environmentally friendly packaging and quick delivery to customers.

It took me some time to get the Intellectual Property rights of my design, creating the packaging and listing it on my shop and Amazon.

It all started with a creative dream and at last I have made it to the finish line. But I am not done here, as I have plans to create more designs. One step at a time though, let’s make the first design a success!

Hope this journey of mine inspires you to create a memorable journey of your own to share.

Comments are closed.